By Enabel – Belgian Development Agency

Rural communities’ access to schools, hospitals, markets and jobs depends on dangerous river crossings. Safe year-round crossing on a stone arch bridge is therefore a foundation for sustainable development.

Population growth and dispersion in Tanzania put a major strain on mobility infrastructure. Unfortunately, the national government struggles to cope with the rapidly increasing demand. Much needed infrastructure projects using conventional techniques, such as steel and reinforced concrete, are often very expensive.

The tried and tested technology of stone arch bridges allows for a decentralized approach embedded within local government structures. This cost-effective method with high local ownership guarantees a long-lasting upgrade of rural roads.

Local material, local labour

We do not have a secure way to enter or leave our village, because of the big Kaseke River. The river complicates our lives; especially when there is a lot of rainfall people cannot cross at all. With the bridge, there is finally a secure way to access our village and transport good to other markets., Magdalena Leonard Kagege – Mayor of Nyabigufa

The commonplace technology for bridges is either concrete or steel. These techniques require a high input of industrial materials and a low amount of labour. However, in rural Tanzania, it is very expensive to use industrial materials, while labour is cheap.

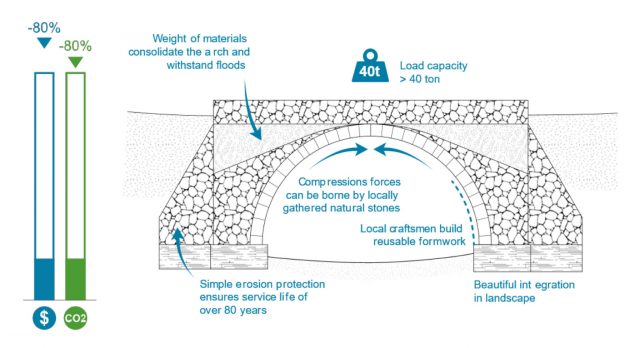

The stone arch technology capitalises on this fact by using readily available local materials in a labour intensive process. This leads on average to a reduction of 80 to 85% in construction costs, and a 50 to 80% reduction in carbon emission due to lower use of cement and reinforcement steel, when compared with conventional construction techniques.

Masonry bridges also avoid some of the disadvantages of conventional alternatives, such as the use of steel or concrete culverts. These frequently break during rough transport over bad roads from industrial centres and, because they are relatively light, they run the risk of being washed away during floods. In addition, such prefabricated elements are sometimes stolen. People dig them out and try to resell them to make a bit of extra money.

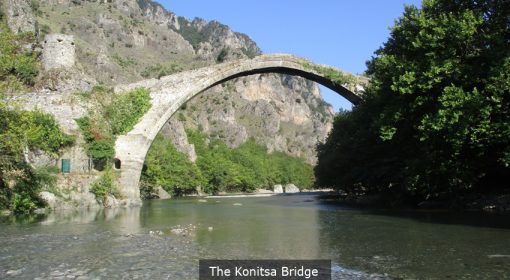

Stone arch bridges have been built for more than 2000 years and some of the early structures are still used today. The Fabricius bridge in Rome for example has two arches spanning 24m each and dates from 62 BCE. Both the design and execution rely on simple rules of thumb that have been tried and tested through time. This avoids the need for complicated design and precision sensitive execution of steel and concrete bridges.

Enabel chooses this cost-effective technology to achieve the same positive outcomes as with more conventional concrete or steel bridges, without the need for significant financial support from the central government. This gives local governments autonomy and allows them to upgrade more rural roads without increasing their budget.

Community involvement

The stone arch technology provides a cost saving of 80% compared to concrete or steel bridges and can be implemented by a public tender procedure. Alternatively, the village and Tanzanian Rural Road Agency (TARURA) can be involved with distributed responsibilities: the village provides stones and sand, TARURA provides supervision and Enabel provides technical support. On top of the cost benefit, the approach creates ownership, builds capacity and empowers local leadership.

An average annual TARURA budget can finance 1 concrete bridge via a public tender procedure. The same budget can instead be used to finance 5 stone arch bridges via public tendering or 10 stone arch bridges by involving the local community.

The village involvement includes the supply of stones, sand, water, timber, but the most important contribution is that of casual labour. This transforms the appreciation of the bridge from a government intervention, and thus not a local responsibility, to a community asset that requires community attention before, during and after construction.

Looking ahead

Enabel has written a construction manual and translated it to Swahili so it can be used by TARURA.

Thanks to close collaboration with TARURA officials during the project, the technique attracts more and more interest. So far, it has already been promoted by the national director of TARURA. Three arch bridges are currently under construction without Enabel support and outside of Enabel’s intervention area, which is currently limited to the North-Eastern Kigoma region. Within the Kigoma region, TARURA has also started the construction of two stone arch bridges outside of the Enabel project.

The project at a glance

- Tanzania has a population of around 55 million, with annual growth rate of 3%

- Bridge construction started in 2018

- Target for 2022 is 70 bridges completed

- Bridge spans range from 1.1 to 31 m

- Bridge budgets range from € 2.400 to € 35.500. This is financed for 80% by the Enabel project and by 20% by local contribution, which are usually in kind contributions such as stones.

- 97% of villagers say they perceive personal benefits after bridge construction was completed.

- 99% of villagers say they perceive benefits to their community after bridge construction was completed.

- Financial costs are 80% lower than an equivalent conventional reinforced concrete bridge.

- Carbon emissions are 80% lower than an equivalent conventional reinforced concrete bridge. This is thanks to less use of cement, no use of reinforcement steel and thus less transport of industrial materials.

Pictures: © Enabel